Technology

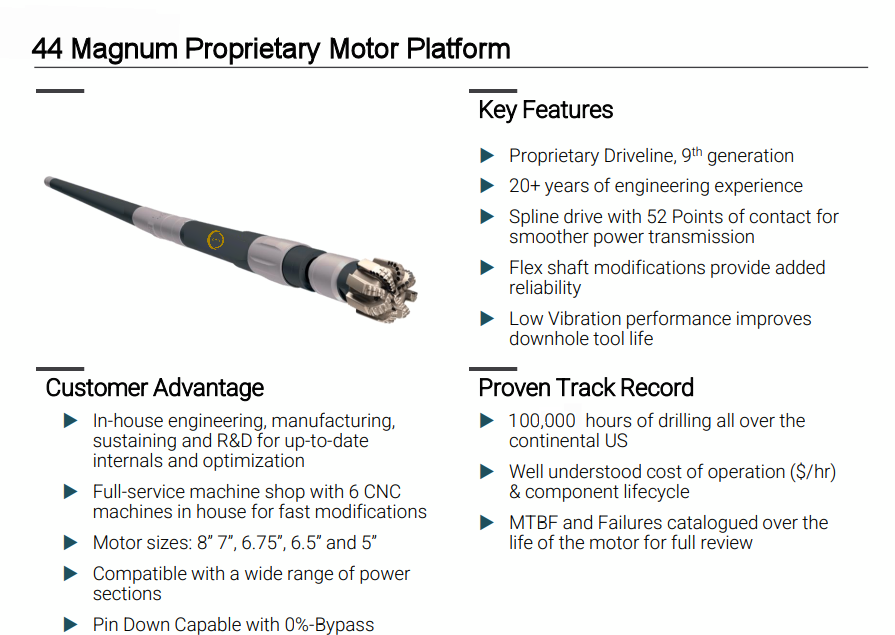

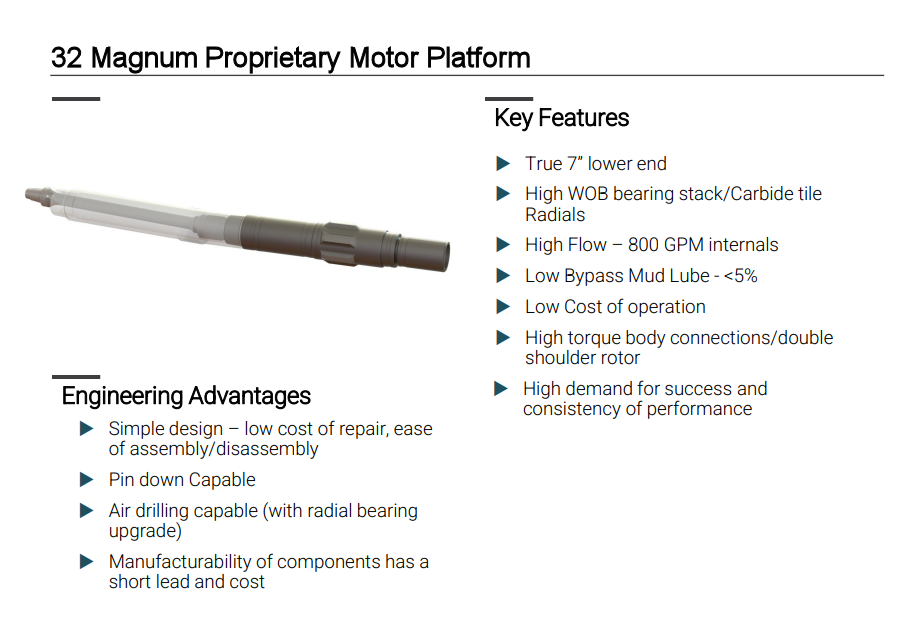

MDS has unveiled our Magnum Series drilling motors, representing a substantial expansion of our product line. The Magnum Series motors represent a pioneering advancement within the drilling motor development sector. Within this line, we offer the 44 Magnum motor model, available in both standard oil lubricated and sealed versions, which excel in terms of torque, bearing load capacity, and extended oil retention. Additionally, we present the 44 Magnum HT model, featuring oil lubrication and sealing, with significantly enhanced torque capacity. Finally, our Magnum 357 mud lubricated model, characterized by a short bit to bend (SBTB) length, possesses the capability to efficiently drill all three sections of a well in a single trip.

Both mud lubricated and oil lubricated Bearing Assemblies are complemented by a distinctive, vibration-free transmission system, ensuring optimal performance, reliability, efficiency, and extended operational lifespan of our tools. MDS Magnum Motors are designed to maintain a consistent RPM and torque at the bit, thereby ensuring a constant rate of penetration (ROP) and extending the lifespan of both the motor and the drill bit. Our proprietary bearings are engineered to withstand prolonged radial and thrust loads, whether during bottom hole drilling or back reaming operations.

MDS offers Drilling Motors with surface-set adjustable 0-3 degree Bent Housing Assemblies or Fixed Bent Housings, all equipped with Rotor Catch Assemblies. Furthermore, our assortment includes near-bit stabilizers and offset kick pads, available upon request. Our motors are conceived with a primary emphasis on reliability and simplicity, delivering exceptional performance in the field and facilitating effortless servicing. All components adhere to rigorous quality standards and are crafted from premium materials, meeting the diverse requirements of various drilling applications.

News Updates

October 3

NEW for October MDS is thrilled to announce the release of our new 5″ 44 MAGNUM Zero-Bypass Performance Mud Motor. Delivering 100% of the fluid to the drill bit without any losses, it is ready to tackle the most challenging drilling conditions. Contact us today to learn more!

June 14

Our 5” 44 MAGNUM Mud Motor with Even Wall Power Section just drilled 3,005 meters (9,858 ft) in one run in the Duvernay area of Alberta!

April 26

Our Rates of Penetration continue to impress: recent runs with our 6.5″ Bearing Pack with 7/8 5.7 Stage power section reached an ROP of 160 m/hr, 165 m/hr, and 170 m/hr (524 ft/hr, 541 ft/hr, and 558 ft/hr) in their respective runs, all in the Duvernay and Montney area. This high ROP translates to greatly reduced drilling time and significant cost savings for our customers.

December 1

MDS 5″ 44 MAGNUM Bearing Pack continuously excels in a monobore application with an Even Wall power section drilling in the Duvernay and Montney area. Our latest runs include 2,777 m, 2,745 m, 2,633 m, 2,440 m (9,110 ft, 9,005 ft, 8,638 ft, 8,005 ft), and many more monobore holes oscillating in the range of 2,200 m (7,217 ft) runs at a 6,000 m (19,600 ft) depth, with hole temps reaching 140°C (284°F) and 32% solids pumped through it.

May 1

Our 44 MAGNUM Motor continues to impress: runs of over 180 hours with an Even Wall Power Section have returned from the Kaybob Field in Northern Alberta in great condition after completing a 2,400m (7,874 ft) run.

April 3

MDS 5″ 44 MAGNUM High Torque motor ran for an outstanding 247 hours, with an average bottom hole temperature of 136°C (277°F), in the Waskahigan Area of Northern Alberta.

March 2

MDS complete 6.5” Mud Lube 357 MAGNUM motor proved very effective, running at 150 m/hr ROP (492 ft/hr), during a 72.5-hour run in Northwest Alberta.

June 1

MDS 5” 44 MAGNUM motor was used to drill a monobore well for a remarkable 2,589 meters (8,494 ft), totaling 238.5 hours in a single run in the Kaybob South Field near Fox Creek, Alberta.

January 6

Customer testimonials continue to flow in:

Our 5″ 44 MAGNUM MDS Technology Motor gave our customer “outrageous outputs consistently seeing 36°/30m” (36°/100 ft).

October 16

MDS Motors have achieved a milestone of 5000 hours without a failure.

July 22

Model 357 MAGNUM, 6.50″, mud lubricated, Short Bit-to-Bend (SBTB) drilling motor is released to the market.

July 8

Model 44 MAGNUM, 8.00″, oil lubricated, sealed, and pressure-balanced drilling motor is released to the market.

November 19

Model 44

MAGNUM, 5.00″, oil lubricated, sealed, and pressure-balanced drilling motor is released to the market.

September 10

Model 44

MAGNUM, 6.50″, oil lubricated, sealed, and pressure-balanced drilling motor is released to the market.”

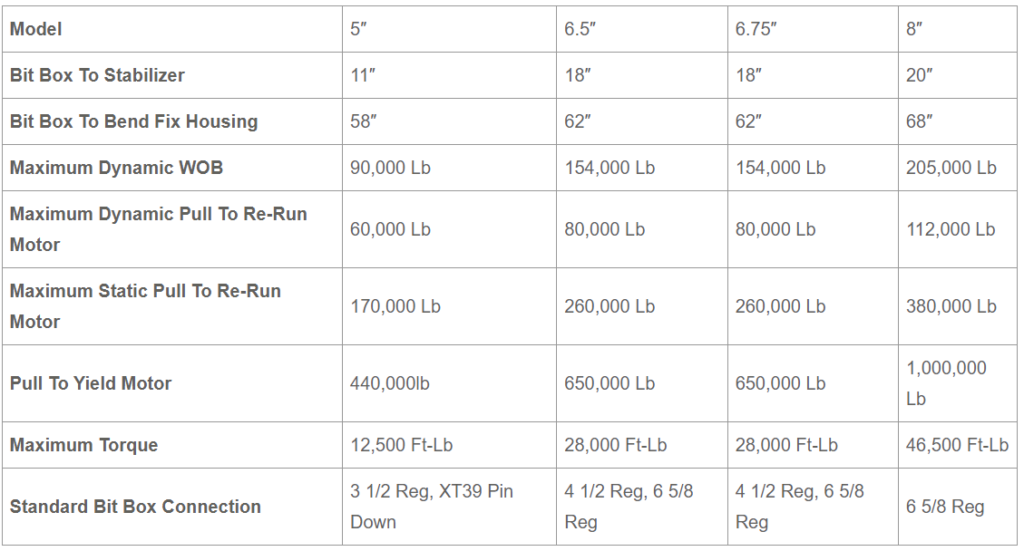

44 Magnum Series Motors - Oil Sealed

| Model | 5″ | 6.5″ | 6.75″ | 8″ |

| Bit Box to Stabilizer | 11″ | 18″ | 18″ | 20″ |

| Bit Box to Bend Fix Housing | 58″ | 62″ | 62″ | 68″ |

| Maximum Dynamic WOB | 90,000 lb | 154,000 lb | 154,000 lb | 205,000 lb |

| Maximum Dynamic Pull to Re-Run Motor | 60,000 lb | 80,000 lb | 80,000 lb | 112,000 lb |

| Maximum Static Pull to Re-Run Motor | 170,000 lb | 260,000 lb | 260,000 lb | 380,000 lb |

| Pull to Yield Motor | 440,000lb | 650,000 lb | 650,000 lb | 1,000,000 lb |

| Maximum Torque | 12,500 ft-lb | 28,000 ft-lb | 28,000 ft-lb | 46,500 ft-lb |

| Standard Bit Box Connection | 3 1/2 Reg, XT39 Pin Down | 4 1/2 Reg, 6 5/8 Reg | 4 1/2 Reg, 6 5/8 Reg | 6 5/8 Reg |

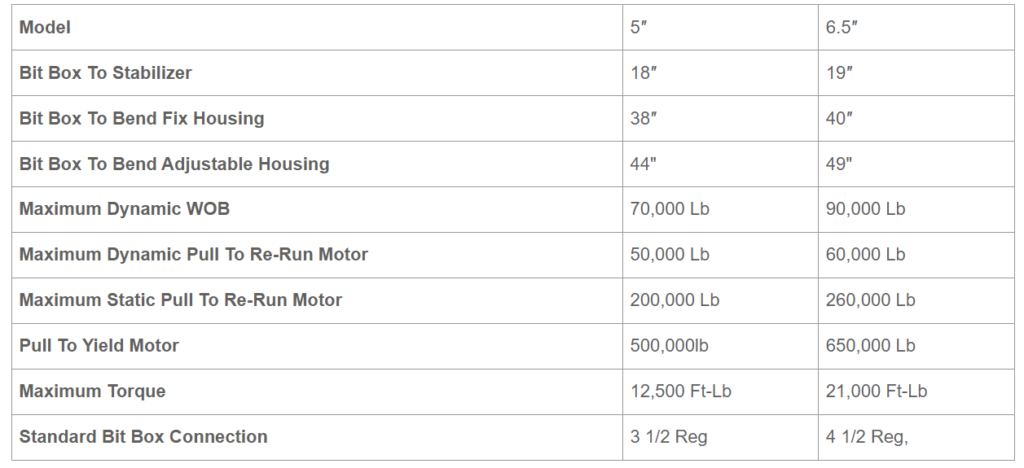

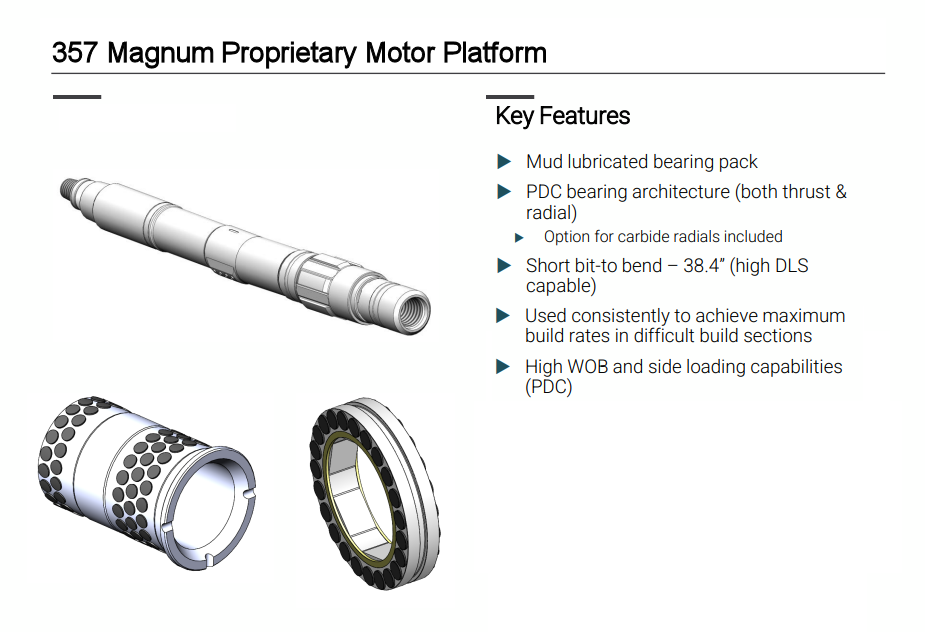

357 Magnum Series Motors - Mud Lubricated

DEDICATED CURVE and LATERAL MOTOR

| Model | 5″ | 6.5″ |

| Bit Box to Stabilizer | 18″ | 19″ |

| Bit Box to Bend Fix Housing | 38″ | 40″ |

| Bit Box to Bend Adjustable housing | 44" | 49" |

| Maximum Dynamic WOB | 70,000 lb | 90,000 lb |

| Maximum Dynamic Pull to Re-Run Motor | 50,000 lb | 60,000 lb |

| Maximum Static Pull to Re-Run Motor | 200,000 lb | 260,000 lb |

| Pull to Yield Motor | 500,000lb | 650,000 lb |

| Maximum Torque | 12,500 ft-lb | 21,000 ft-lb |

| Standard Bit Box Connection | 3 1/2 Reg | 4 1/2 Reg, |

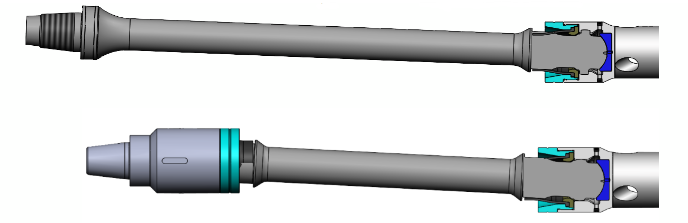

Transmission Designs

Magnum JRM Transmission

Magnum Drilling Solutions has developed a robust and inexpensive transmission technology that is utilized and interchangeable to all motor product lines.

This technology is a trade secret of Magnum and all IP and manufacturing rights are proprietary.

License agreement for the sale and manufacture of the transmission is available.

Quick Overview

• Utilizing a Spline as the anti-rotation mechanism, this transmission eliminates complexity and cost.

• 52 points of contact reduce backlash and maintain consistent high torque transfer mechanism

• Both flex shaft and CV styles are utilized depending on the application

• Flex shaft for High Torque Premium Power Applications (Spline direct to Rotor)

• CV for conventional and shortened transmission applications (Spline By Spline)